Elevating industrial safety with digital monitoring solutions and IOT

Elevating industrial safety with digital monitoring solutions and IOT

Partner

Henkel / LOCTITE® Pulse

2020 - 23

Our services

Product Strategy

Research

App Architecture

UX/UI Design

Design System

Development

Henkel, the German industrial manufacturing company, is revolutionizing Industry 4.0 with their innovative thinking and technology.

Over a three-year partnership, together we contributed to define and develop LOCTITE® Pulse, an Industrial Internet of Things (IIoT) Solution. Addressing the core issue of real-time monitoring and prediction elevating plant safety and productivity.

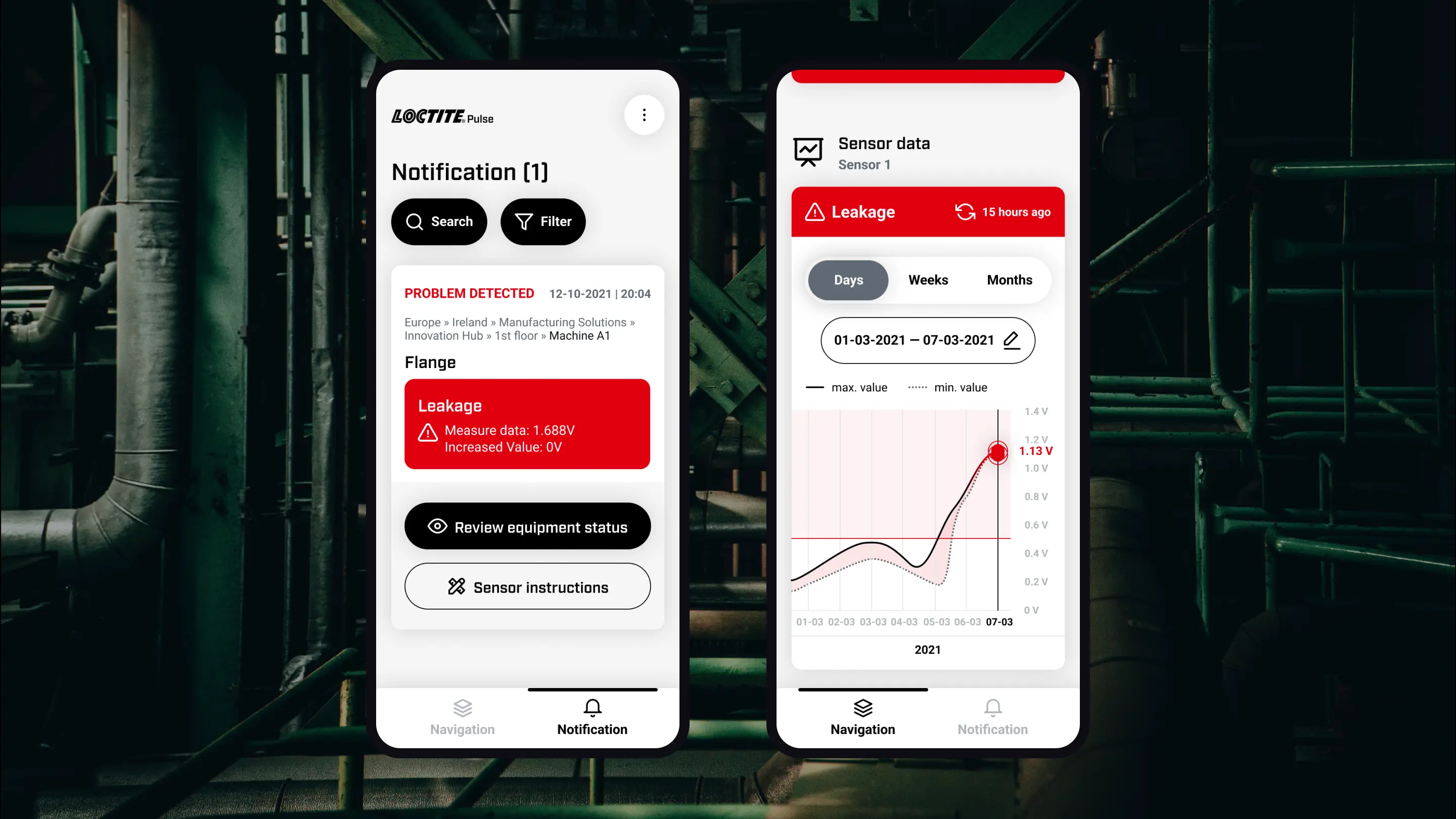

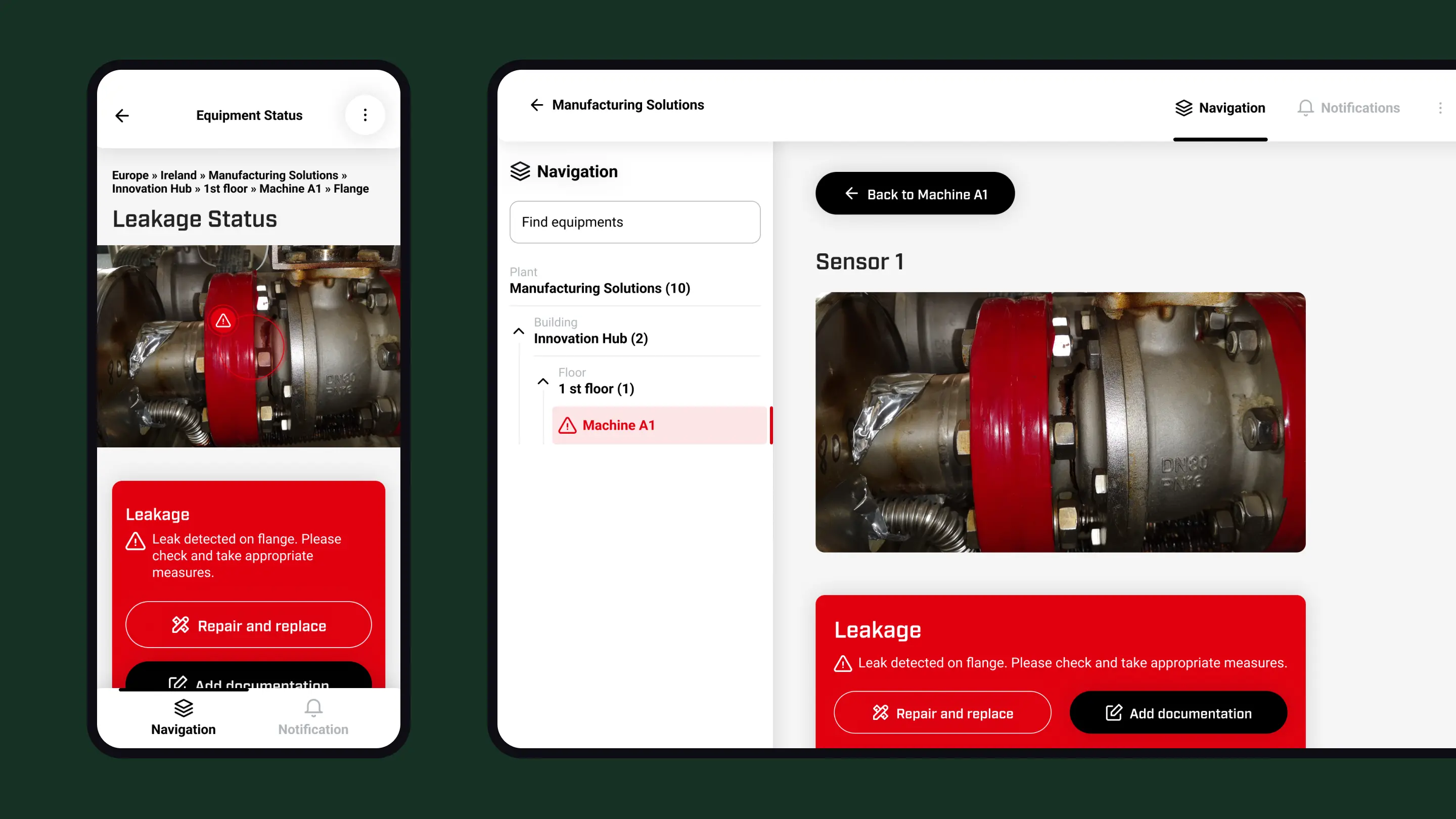

The LOCTITE® Pulse web-app became the nexus, providing plant managers and technicians with actionable insights, configuring factory settings, and fostering proactive maintenance.

≈10x

safer work environments

≈10%

reduced maintenance costs

≈20%

increased equipment uptime

It all started in Berlin establishing a user-centric mindset

Back in 2020 our collaboration with Henkel commenced with a pivotal goal: to revamp their initial tool into an user-centric solution.

The transformation began with a clear challenge — bring cohesion to the team and establish a shared mindset — and how? by adhering to agile methodologies in combination with Design Studio sessions.

Understand the tech in order to realize solutions

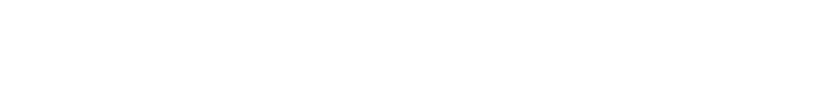

We first had to understand the technology behind the sensors that Henkel has created.

“Imagine a company acquires Henkel's sensors and installs them on every equipment. Now these sensors monitor the equipment to the point where our solution can predict that a leak is about to happen and automatically alert a technician who can fix the problem before it occur.”

Source: LOCTITE & TEROSON Europe "Behind the Pulse : Experience Smart Maintenance"

5 prototypes,

10 interviews,

2 surveys and

on-site lab testing

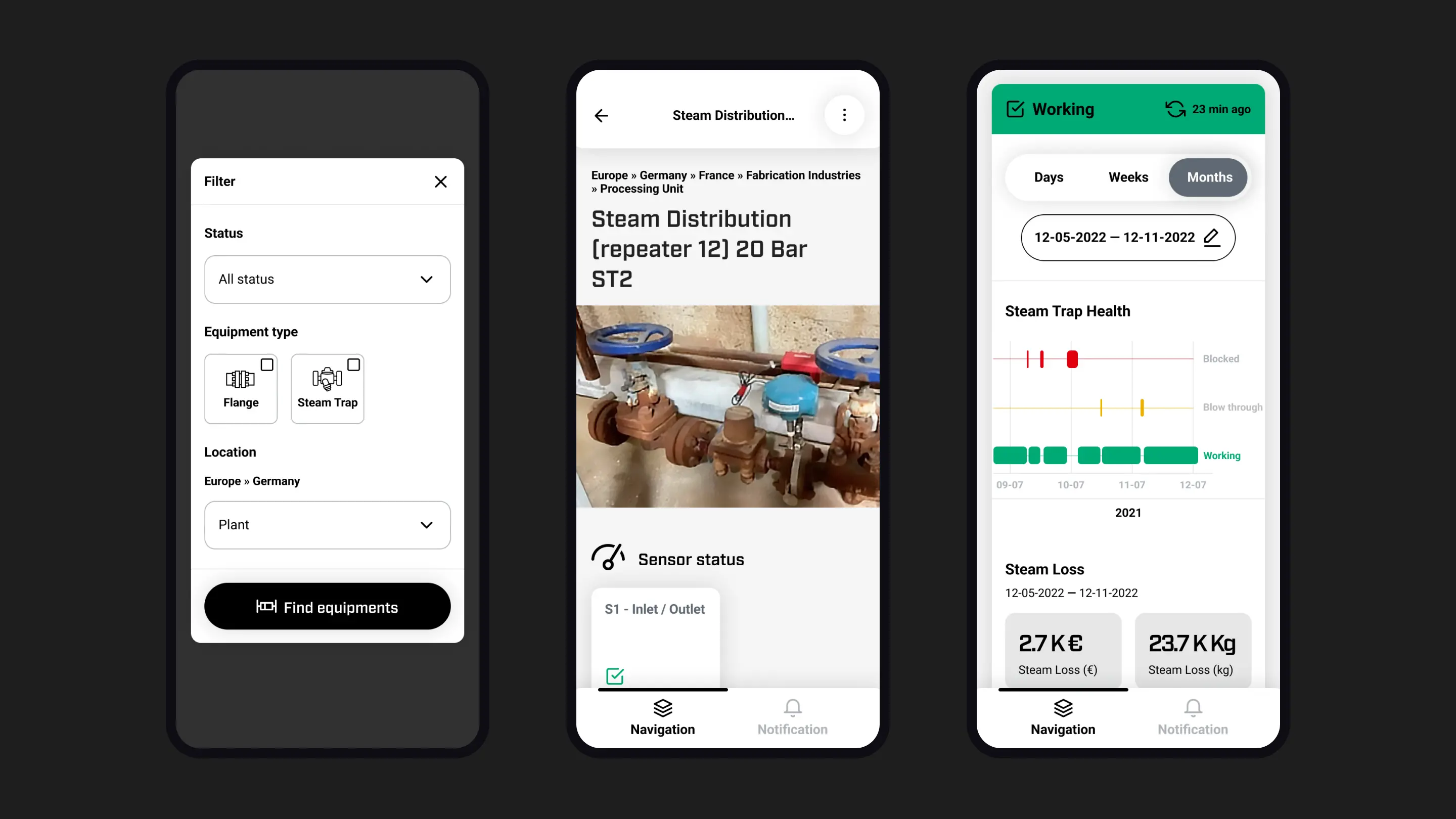

In order to validate our assumptions, UX design approach was grounded in real-world insights. Engaging plant technicians and managers through interviews and surveys enriched our understanding of their practical needs and pain points.

However, the true epiphany unfolded during on-site lab testing, where we were able to observe how technicians use our solution in combination with real equipments and the environment around them.

Powerful UI Design

focusing on accessibility

Translating LOCTITE® Pulse’s brand identity into a digital space demanded meticulous attention. The UI was crafted with a keen eye on accessibility, ensuring ease of use for diverse users across different continents.

Moreover, its adaptability to varied factory environments was a cornerstone of our design ethos. ”How can we guarantee the best performance of the app in a low light and rush environment?“ By a clear navigation, big components and clear actions.

Enabling the engineers

Our last step on the way was to answer the question: ”How to include an external development company into the equation?” Enabling the engineers by an excellent documentation, collaborative discussion and establishing a workflow that streamlined the quality assurance process.

Circles of Success

LOCTITE® Pulse stands as a testament to the synergy of user-centric design and agile collaboration, redefining the Industry 4.0 landscape.

The success of this collaboration was not only in the seamless execution of the project but in the shared vision and achievement fostered through transparency, trust and iterative methodologies.

Award winning solution

Henkel received multiple recognitions for LOCTITE® Pulse, including the 'Engineering Product of the Year 2023' award by the DEA and the 'Digital Innovation Award 2023' by BEMAS.